| Unit Price: | 1~6 USD |

|---|---|

| Payment Type: | T/T,L/C,Western Union |

| Incoterm: | FOB |

| Min. Order: | 500 Piece/Pieces |

| Delivery Time: | 15 Days |

Model No.: LM-15L001

Copper Die Casting Parts Details

Die casting is a pressure casting parts, is the use of installed pressure casting die casting machine die casting machine, the heating liquid copper, zinc, aluminum or aluminum alloy metal is poured into the die casting machine feeding port, by die casting, casting a restrict mold the shape and size of copper, zinc, Aluminum Parts or aluminum alloy parts, this part is usually called die casting. Copper die casting has good fluidity and plasticity, and colleagues have good thermal conductivity, small proportion and high processing, and durable.

Brass Die Casting Product Specifications:

1. Customized Brass Die Casting

2. Production Process: Die Casting

3. OEM seivice

4. Certification: ISO:9001

5. We can provide the sample

Advantage

1. We have rich experience in copper die casting, we have advance equipment and best management.

2. We have been standing in the customer's point of view, with the production of the best for the customer.

3. With our credibility and good ideas, we have established a good relationship with customers in some countries.

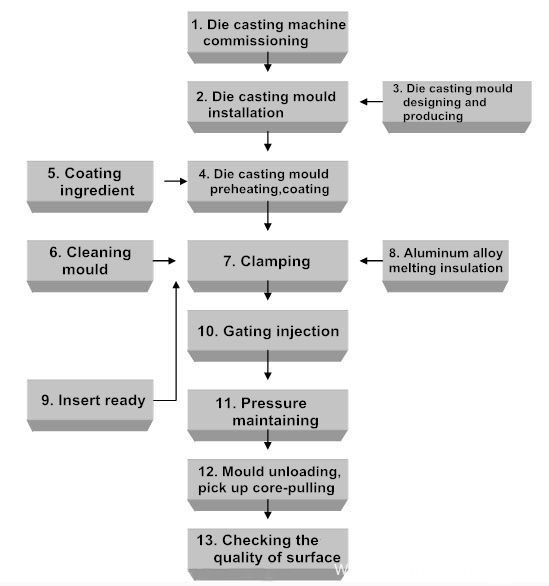

Copper Die Casting Product flow chart

Materials of copper alloy die-casting: Cu 59-1, Cu 63, Cu62;

The precision of the Cu die casting part: ±0.15mm;

Smoothness of rough part: Ra3.2;

Shrinkage rate of brass die casting products: 0.6%;

Material wastage rate: 6%;

Cu die-casting machining allowance: 0.5mm~0.7mm;

Surface preparation methods: Sand blasted, Shot blasting, Powder coating, Painting, Plating, Polishing.

Our company's production equipment and management system

copper die casting production equipment: L.K brand die casting machine From 160T, 200T, 280T, 400T,

CNC machining center: 6;

CNC lathe machine: 12;

Work days of one week: From Monday to Saturday;

Shift work: 2 shift per day;

Working hours: From AM 8:00 to PM 4:30;

2D and 3D drawing Software: AutoCAD, UG, Pro/E, SolidWorks 2015;

QC control: New type NANO CMM, FPI M5000 desktop metal analyzer, Mechanical properties tester.

My company`s strengths of Brass Die Casting Parts, CNC machining, and QA control.

Product Categories : Die Casting Parts > Copper alloy die casting parts