Find Car Motorcycle Cnc Service, Cnc Machining Aluminum, Cnc Turning Parts on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

| Unit Price: | 0.37~3.39 USD |

|---|---|

| Min. Order: | 1 Piece/Pieces |

1 | Application | Auto /Moto Parts, Machinery Parts, Hardware Accessories, Agricultural Machinery, , Medical EquipmentElectric Motor Products, etc |

2 | Materials | Metals: Aluminum, Stainless Steel, Brass, Copper, Titanium, Mild steel, Tool Steel, Inconel |

Plastic: POM(Derlin/Acetal), Nylon, ABS, PEEK, PVC, PET, Polypropylene | ||

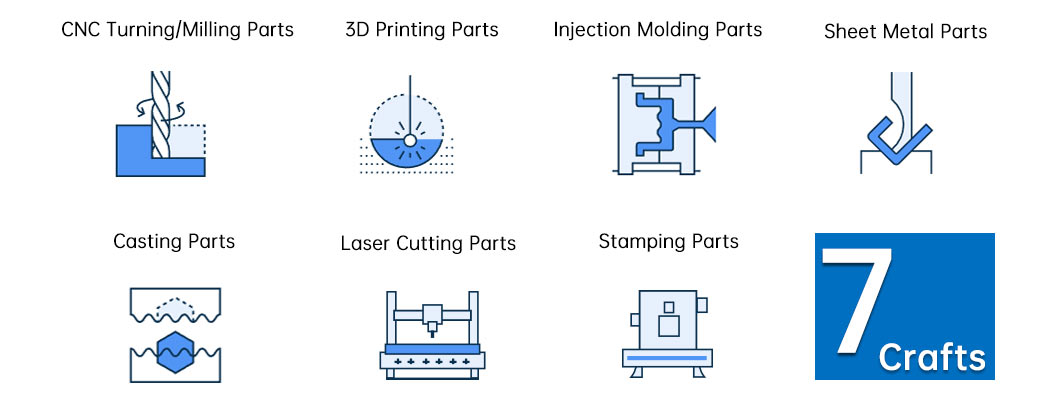

3 | Machining | Cleaning,Turning, Milling, Drilling, Grinding,Sheet Metal,Welding,Cutting,Discharge,3D Printing etc |

4 | Surface Treatment | Polishing, Deburring, Chrome Plate, Ni Plated, Zine plated, Silver platinng, etc |

Clear anodizing, Anodizing black, Carburizing Nitriding, Heat Treatment, etc | ||

5 | Detection Equipment | DMG five-axis CNC machining center,Mazak five-axis CNC machining center,Mazek four-aixs CNC machining center,Mazak gantry machining center,FANUC four-axis CNC machining center,and Mazak CNC lathe. |

KONLIDA has CMM and Optical image measuring instrument,tool measuring instruments, roughness meters andother testing instrunments to provide control and parameter basis for product design and quality. | ||

6 | Certification | GB/T19001-2019-ISO 9001:2022, ISO13485:2015, AS9100D |

7 | PaymentTerm | T/T, LC at sight, PayPal, Credit card |

8 | Delivery Time | 10days for sample, 25days for mass goods |

Our Advantages | *With a professional technical and management team of more than 100 people,24 hours of uninterrupted processing andmanufacturing, and equipped with a post-production surface treatment plant, * it can meet one-stop processing and assembly services. *Corporate philosophy: All problems end with us Reliable Quality *Moderate Price *High precision *Quick Response Excellent After-Sales Servic |

Product Categories : CNC Maching Parts